Food packaging materials, their vapour permeability properties and applications

This page covers many of the main packaging materials used for food and snack products, including the types of foods they're typically used for, and their vapour permeability requirements. It also covers several food types and their vapour permeability requirements. For more general food and vapour permeability considerations click here

This page covers many of the main packaging materials used for food and snack products, including the types of foods they're typically used for, and their vapour permeability requirements. It also covers several food types and their vapour permeability requirements. For more general food and vapour permeability considerations click here

1. Polyethylene Terephthalate (PET)

- Types of Food: Beverages (bottled water, juices, soft drinks), snack foods (potato chips, pretzels), fresh produce (salads, fruit).

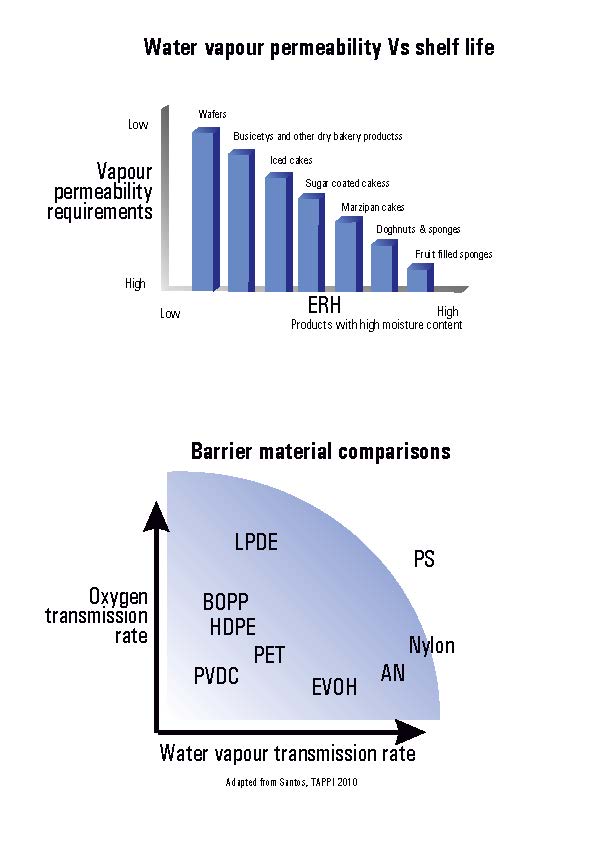

- Vapour Permeability: Low vapour permeability; provides a strong barrier to oxygen and moisture. Suitable for products sensitive to both oxygen and water vapour, such as carbonated drinks and chips, where moisture can cause sogginess and oxidation can lead to rancidity.

2. Polypropylene (PP)

- Types of Food: Bakery items (bread, cakes, cookies), fresh produce (salads, vegetables), dairy (yogurts, butter).

- Vapour Permeability: Moderate moisture barrier and low oxygen permeability. Good for products that need moisture protection but not necessarily high oxygen barrier, like baked goods that require some moisture retention to maintain texture.

3. Low-Density Polyethylene (LDPE)

- Types of Food: Frozen foods (vegetables, fruits, seafood), bread, meat products.

- Vapour Permeability: Moderate to high vapour permeability. Good moisture barrier, making it ideal for frozen food packaging to prevent moisture loss and freezer burn.

4. High-Density Polyethylene (HDPE)

- Types of Food: Milk, juice bottles, cereal liners, dry goods (pasta, rice).

- Vapour Permeability: Low vapour permeability, strong moisture and oxygen barrier. Suitable for products like milk and cereals that are sensitive to moisture and oxygen, which can lead to spoilage or texture changes.

5. Polyvinyl Chloride (PVC)

5. Polyvinyl Chloride (PVC)

- Types of Food: Fresh meat, poultry, fish, cheeses, pre-cooked meals.

- Vapour Permeability: Moderate moisture barrier but high oxygen permeability. Used for products that benefit from a controlled atmosphere, allowing some oxygen to pass through (e.g., fresh meat needs to retain its red colour via oxygen exposure).

6. Polystyrene (PS)

- Types of Food: Yogurt pots, egg cartons, take-out containers, dairy products.

- Vapour Permeability: High vapour permeability. Provides insulation but has poor barrier properties for oxygen and moisture, making it suitable for short shelf-life items or items that don't require extended protection.

7. Polyamide (Nylon)

- Types of Food: Meat, cheese, vacuum-packed products.

- Vapour Permeability: Low vapour permeability. Excellent barrier to oxygen, but moderate-to-poor moisture barrier. Suitable for vacuum packaging to prevent oxidation and extend shelf life.

8. Aluminium Foil

- Types of Food: Chocolate, coffee, ready-to-eat meals, confectionery.

- Vapour Permeability: Excellent moisture and oxygen barrier (almost zero permeability). Perfect for products highly sensitive to moisture and oxygen, such as chocolate and coffee, where freshness and flavour preservation are key.

9. Cellophane

- Types of Food: Bakery items, candy, fresh produce, gift packaging.

- Vapour Permeability: Moderate to high vapour permeability. Provides a decent barrier to moisture but allows some gas exchange, making it suitable for produce and bakery items that need to breathe and release moisture.

10. Metallized Films (e.g., Metallized PET, Metallized PP)

- Types of Food: Snack foods (potato chips, crisps, granola bars), dried foods.

- Vapour Permeability: Extremely low vapour permeability. These films are used when an excellent moisture and oxygen barrier is needed, ideal for preserving the crunchiness and freshness of snack foods and dry goods.

11. Paper and Paperboard (Coated/Uncoated)

- Types of Food: Dry foods (flour, sugar), frozen foods, bakery items, cereal boxes.

- Vapour Permeability: High vapour permeability unless coated. Typically used with coatings (wax, plastic) to improve moisture resistance for products like frozen foods. Coated versions offer better moisture and grease resistance, while uncoated paper is more suitable for dry foods.

12. Ethylene Vinyl Alcohol (EVOH)

- Types of Food: Meat, poultry, dairy, fresh vegetables.

- Vapour Permeability: Excellent oxygen barrier but permeable to moisture. Often combined with other polymers (like PE or PP) to create a multi-layer film that offers both oxygen and moisture protection, ideal for perishable foods like meat and dairy.

13. Biodegradable/Compostable Films (PLA, PHA, etc.)

- Types of Food: Fresh produce, snack foods, ready-to-eat meals, bakery items.

- Vapour Permeability: Moderate to high vapour permeability depending on the material. These films are increasingly used in packaging due to sustainability demands, but they often need additional coatings or multi-layer designs to achieve adequate moisture and oxygen barriers for foods.

14. Glass

Types of Food: Jams, sauces, beverages (wine, beer, soft drinks), baby food.

Types of Food: Jams, sauces, beverages (wine, beer, soft drinks), baby food.- Vapour Permeability: Virtually zero vapour permeability. Glass is an excellent barrier to all gases and moisture, making it ideal for long shelf-life products that require complete protection from external environmental factors.

15. Tinplate/Steel Cans

- Types of Food: Canned vegetables, fruits, soups, ready meals.

- Vapour Permeability Virtually zero permeability. Tinplate and steel provide an almost perfect barrier to moisture, oxygen, and light, making them ideal for long-term storage of highly perishable items like fruits, vegetables, and ready-to-eat meals.

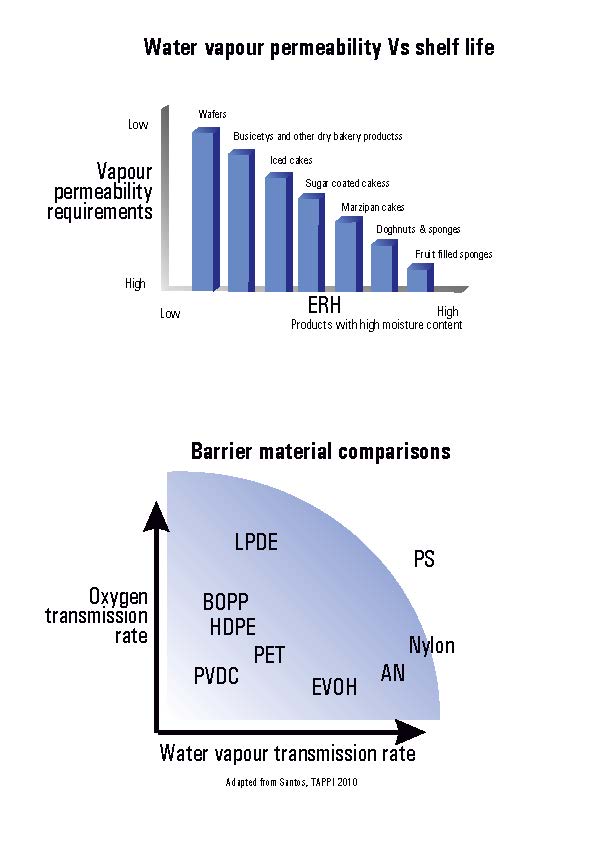

Vapour Permeability Requirements by Food Types:

- Dry foods (cereals, snacks, grains): Need low moisture permeability to prevent staling and spoilage.

- Moist foods (cheese, fresh meat, bakery items): Moderate vapour permeability is required to retain moisture, while also needing oxygen control to prevent microbial growth.

- Highly perishable foods (fresh produce, dairy): Need precise control of oxygen and moisture permeability to prevent spoilage, mould growth, and degradation. Each product has a unique requirement – even different types of the same produce

- Frozen foods: Require a strong moisture barrier to prevent freezer burn and dehydration.

- Snack foods (crisps, pretzels): Low vapour permeability to maintain crunchiness and freshness by preventing oxygen and moisture ingress.

| |

This page covers many of the main packaging materials used for food and snack products, including the types of foods they're typically used for, and their vapour permeability requirements. It also covers several food types and their vapour permeability requirements. For more general food and vapour permeability considerations click here

This page covers many of the main packaging materials used for food and snack products, including the types of foods they're typically used for, and their vapour permeability requirements. It also covers several food types and their vapour permeability requirements. For more general food and vapour permeability considerations click here 5. Polyvinyl Chloride (PVC)

5. Polyvinyl Chloride (PVC) Types of Food: Jams, sauces, beverages (wine, beer, soft drinks), baby food.

Types of Food: Jams, sauces, beverages (wine, beer, soft drinks), baby food.